New Production Line Facility

Client:

Confidential

Build Type:

Traditional & Refurbishment

Value:

£312K

Size:

4650 m2

Introduction

Our team was appointed to provide mechanical environmental services to a new production line facility in Barrow.

Housed within a large existing industrial unit, to be refurbished as part of the works, a new steel framed extension was added to increase floor area to accommodate the new manufacturing process.

Challenge

The challenge was to provide a design that minimised disruption to the existing facility, navigating and coordinating with a multitude of existing services and steel structural elements at roof soffit level. The modification of existing systems to integrate the new was also a factor.

The new installation had to consider safe working practices at high level internally and at roof level. All works were to be provided within a programmed time frame to suit the delivery of the new production line machinery.

Solution

Designed using in-house teams to meet the client specification and statutory regulations, the required services included fresh air ventilation, heating, and controls. Our team designed, delivered to site, and completed the installation within a project duration of 16 weeks. We methodically planned the works to ensure the safety of all parties.

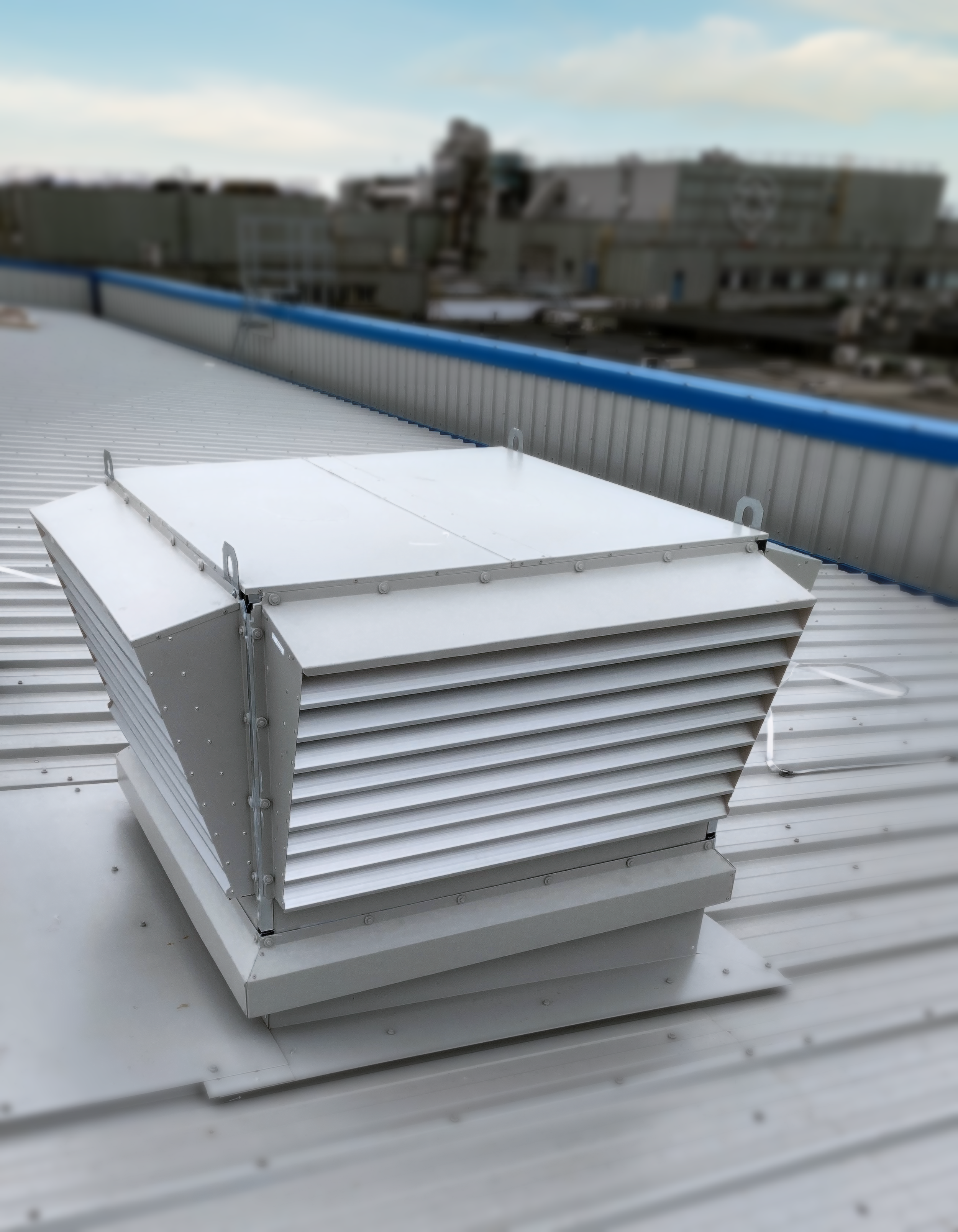

Project features included the design and maintenance of bespoke steam heated roof ventilation units, whilst utilising 3D design software to coordinate with the existing building structure and services, minimising onsite installation times.

Result

A successful mechanical project tailored to meet the needs of the client and handed over on time and within budget.